Integrating the ‘Constructioneering’ Workflow Together

The How and Why of the Topcon and Bentley Partnership

Digitalisation and new technologies with the ability to revolutionise the geospatial industry are creating a new playing field for mapping and surveying professionals. This evolving landscape is also reshaping the industry, with new entrants gaining ground and established players seeking to collaborate and combine their specialist areas of expertise in order to offer a total solution. Wim van Wegen, content manager of ‘GIM International’, met with Ted Lamboo, senior vice president of strategic partners at Bentley Systems, and Ewout Korpershoek, executive vice president at Topcon Positioning Systems, at Bentley’s 2017 Year in Infrastructure Conference in Singapore. They discussed the partnership between the two companies, their views on where the industry is heading and much more.

Topcon and Bentley joined forces around a year ago, in November 2016, to serve the construction industry, or ‘constructioneering’ as you call it. What is the difference between constructioneering and building information modelling (BIM)?

Ted Lamboo: “There are many definitions of BIM, as there are probably with GIS. In our case, we regard the word ‘building’ as a verb, not a noun. Unfortunately a lot of other people translate ‘building’ to mean a physical building, rather than the process of building something. We’ve always said that the ‘information modelling’ part of BIM should actually be seen as two different axes – there is information management and there’s information mobility, so that means that BIM is on both the horizontal and the vertical axis. You see that reflected in constructioneering as well: the necessity to manage the information smartly and pass it on through the workflow, and the necessity to let information travel from one spot to another. In the bigger definition of BIM, it covers the entire life cycle – you’ve got BIM level 1, 2, 3, 4 and 5, although most organisations are not that far – whereas constructioneering actually defines a shorter period from engineering to construction, with the data handover at the end. One true difference from BIM is that constructioneering is not trying to resolve subjects that get into the operational phase. I also believe that constructioneering is more of an applied science, because it results in a physical construction at the end of the process, whereas BIM is still a bit too much a ‘something that happens at the office’ experience – although that’s not our intention; we want the data to be mobile. But maybe BIM is a more global definition, and constructioneering is a narrower definition for particular heavy civil industry.”

Ewout Korpershoek: “I agree. BIM is more of a holistic approach to a process that, via constructioneering, starts connecting all the practical activities that need to happen. The whole BIM process involves a lot of work – from planning, conception to scheduling, detailed building and life-cycle management – but the actual building is a fairly limited part in this total timeline. When I hear other people talking about BIM, they often mean the whole process that spans all those activities, whereas we really look at what is happening in the field. Other people often downplay or forget the actual work in the field – they see it as a necessary evil – but given our expertise we believe that is really where significant progress can be made. Together with Bentley we came up with the term ‘constructioneering’ to describe what is a very practical sub-activity inside any BIM process. In addition to that, BIM’s origins lie more in the design profession. Often when our customers say ‘I need to do BIM’ they mean ‘I need to work in 3D’. So suddenly instead of a paper-based plan they get a coordinate file, but that’s not maximising the true capabilities of BIM. So that’s why we came up with the term ‘constructioneering’, which goes beyond just making the move from 2D paper plans to 3D coordinate files.”

In 2017 Topcon celebrated its 85th anniversary. How did you evolve to become a global player in the surveying market, and where do you stand now?

Ewout: “Traditionally, an important part of our focus has been on the high-tech survey business where, through time, we have added new technologies such as GNSS, laser scanning, imaging and machine control to serve our customers’ growing needs. We acquired or developed directly related technologies like telematics, inertials and specific software additions, and we entered the agricultural field through several acquisitions. Our main drive has always been to be at the forefront of technology and provide cutting-edge solutions for mobile workforces to solve their positioning and data needs. Today we’re adding cloud communications, Internet of Things (IoT) and we are partnering with companies like Bentley as important components of our mission to offer a truly real-time platform for automation of all position-related fieldwork. This places us right at the heart of what we call the ‘intersection of infrastructure and technology’. We are committed to serve our customers through leading-edge technologies, solutions and partnerships in order to increase the quality and performance of their daily work.”

Bentley Systems was founded in 1984, originally as a CAD and GIS software development company. Do you agree that the revolution in sensor technologies enabling massive collection and real-time processing of various geodata, including point clouds, marked a key turning point for your company?

Ted: “Well, I would prefer to define Bentley a little differently because we have been promoting asset management for a very long time now. Big data is created at two moments; the first type is the data you collect to define the geometry that you’re working with in the field – point clouds, scanning, photos, there are many sources of big data in the survey process. The second type of big data is created at the very end of the asset management life cycle when sensors measure vibrations, traffic, CO2 pollution and so on. That’s a different type of sensor data and obviously involves different types of sensors. I would say it has always been in Bentley’s roots as we have always supported raster, we have always supported aerial photography behind CAD, we have always supported point clouds and have been very good at unlimited file sizes – that’s important because we have always been involved in big infrastructural projects, and big projects come with big data. Nowadays, big data has become much bigger and point clouds are much bigger – the terabytes are flying around – but it’s now up to the user to choose which data and how much of it they want to use, during either the engineering, the construction and/or the operational asset management phase.”

Bentley has a strong global presence, and Topcon has a global network of subsidiaries and affiliates and a network of distributors. Is your partnership a push for further global expansion in tandem?

Ewout: “The main driver for the Bentley-Topcon business partnership is the opportunity that we see in automating a market that we jointly consider as being core, which is related to construction, infrastructure and management. The reality is that Topcon customers traditionally work out in the field and Bentley customers work in the office. That has been the status quo, with data basically carried back and forth. In today’s connected environment and with the current technologies, there is absolutely no reason why data created and collected by Topcon systems in the field could not immediately be used, analysed, packaged and reviewed in the office. That’s what makes our cooperation even more important; technology has been driving us closer. It’s a very logical step in my opinion.”

Ted: “Bentley is a mixture of direct business that we do globally and also global partnerships. In terms of size, our two companies are pretty similar – Bentley employs 3,000-plus people, Topcon around 6,000. Topcon makes physical products and has more obligations in terms of manufacturing and inventory shipment, which we in the software world don’t have. In the field we represent different areas of the market – Bentley benefits the engineer in the office, and Topcon reaches the surveyor in the field – so we visit different users, and that’s where the synergy comes from. As the workflow becomes more integrated, there is a growing opportunity for both of our companies and for our partners to pick up a bigger part of the workflow and sell it as a complete solution.”

Topcon started out as a manufacturer of surveying devices. These gradually evolved into total stations which are advanced systems packed with electronics and software nowadays. How can your two companies reinforce each other, given today’s rapid technological and societal changes?

Ewout: “The opportunity to reinforce each other is one of the main drivers for our relationship. It’s not our intention to heavily invest in developing products similar to Bentley’s, and likewise it’s not Bentley’s ambition to start developing hardware. Developing hardware is our core DNA, and whereas hardware and software used to be fairly separate we’re now seeing them increasingly merging. Customers no longer get excited about a mobile phone with a touch screen, what matters are the apps and functionalities. That’s the opportunity in our relationship.”

Ted: “A phone is not smart without the apps, and the apps are useless without proper hardware that can understand them. So the integration necessities between hardware and software are bringing both worlds closer and closer together in many ways.”

Which developments can surveyors expect over the next five years?

Ewout: “I’m a surveyor myself, and I don’t expect the core surveying profession to disappear. A lot of new markets offer opportunities for growth and the expansion of the activities. In the future, the surveyor is transforming from somebody who physically stands in the mud and puts stakes in the ground, into a data and quality manager. It’s a process that we’ve already been seeing over the past couple of years, especially in the construction industry. This will continue and it opens up a number of new opportunities for the traditional surveying or geodesy professional to expand into all sorts of applications and markets where data management and data quality are critical.”

Ted: “As a former surveyor as well, I would like to add that the surveying profession is becoming broader. Both Topcon and Bentley encourage the whole concept of continuous representation of reality – before, during and after construction. In the past we didn’t have the tools and the capability of processing the data so quickly that the interim results would be beneficial to the process, but that has really become much more pervasive now and, as a result, the need for surveying has increased. That’s good for Topcon, but it’s also good for us because it provides more information during the process. So we both encourage more frequent surveying and a broader collection of data than the narrow geometry that we used to ask for in the past.”

Ewout: “To put it very simply, you could say that the specialism of the traditional surveyor was to model reality in a very simplified form, creating 2D maps. That was generally a post-processing process; you captured data and you took it back to the office, so the simplified model that was created was never truly current and up-to-date. Today we have technology that allows us to capture nearly continuously – and it will soon be continuously – all the information that we can visually see in all its dimensions. That means that the surveyor’s product is changing and the application opportunities are growing tremendously. And I believe that’s the changing role of the surveyor.”

GNSS technology is a major area within the positioning business, alongside total stations. Which key developments do you foresee in GNSS technology, what are their implications for the surveying profession, and how will the developments affect your consumer base?

Ewout: “GNSS has become a major positioning technology for both survey and construction execution operations. When Topcon introduced the first dual-constellation receivers in 2000, we could already see the benefits of more satellites, providing higher uptime, better accuracy and faster initialisation. Since then, GNSS technology has rapidly evolved to the current high-performance levels, providing the basis for increased adoption as the standard for many new and existing applications. The next step in this journey is the deeper integration with other sensors and positioning solutions. There are good examples in the use of GNSS in our construction machine control applications; when coupled with advanced inertial technology, the user is able to operate his machine at much higher speed and performance levels. By combining different sensor technologies we offer more robust, accurate and reliable positioning solutions that open up both new markets and new opportunities in existing markets.”

Today’s airborne, terrestrial and mobile laser scanners are able to capture billions of 3D points in the blink of an eye. However, the processing of the massive volumes still requires a lot of human intervention. How can cooperation between Topcon and Bentley help to solve this?

Ted: “Let me first deal with the volume, which is also a great example of our cooperation. There are a number of new technologies and I use the ContextCapture and the photogrammetry side as a fantastic example of that. As mentioned, both of us studied geodesy and in our day you had to study for years in order to understand photogrammetry and use the technology in practice. It was a lot of work; you could only overlay two photos with each other at any one time. Once you had done the overlap part you could move on to the next couple of photos. Now we just throw tens of thousands of photos into a black box, that black box does the photogrammetry for us. In other words, the process has been simplified a lot – you don’t have to be a photogrammetrist in order to do photogrammetry using ContextCapture, so there’s been a tremendous simplification. Of course, you still need to understand a couple of first principles about control points and suchlike, but the software helps you a lot. It guides you in what you need to capture and it warns you if there’s not enough overlap. But there’s still a lot of data and the processing still takes a lot of horsepower, so what both Bentley and Topcon are doing is moving applications into the cloud, where we have an unlimited amount of processing power. We have one particular user who is using a thousand CPUs in the cloud at the same time, just to speed up the processing. Scalability with the cloud is literally endless, and we’re clearly scaling up to take advantage of that. There’s a lot of commitment between Bentley and Microsoft with their Azure cloud processing solution, and I’m sure this is just the start.”

Ewout: “The level of human intervention has definitely not increased, in fact it’s becoming less and less. If I consider how much manual labour was involved back when I was using a theodolite and a distance metre to calculate coordinates, there was more manual labour than computer time – although computers in those days were so slow that they also took two days to calculate a couple of hundred coordinates! But technology continues to evolve, and it’s human nature that we will always push the envelope: computers get better, storage gets bigger, CPUs get faster and at the same time sensors are being developed that capture millions of points rather than thousands. We’re always going to be at the edge, and in a sense customers expect that from us; if we want to develop cutting-edge technologies, they expect us to be at the forefront of technology. One big focus for both our companies is definitely that, with increased computing power and intelligence at your fingertips, the human interactions can be minimised and dumbed down so far that a lot of the previous specialism is eliminated. We will certainly see this more and more going forward when machine learning starts to play a more important role. Knowledgeable human interaction will still be necessary, if only for determining mistakes and errors and judging quality. That brings us back to the point we discussed earlier; the role of the surveyor is changing from a data processor to a quality manager.”

Ted: “The functions and processes have been simplified, but they are being replaced by the need to interpret, assess and know what do with the outcome. So I actually think the human brain is being used at a higher level than merely learning formulas off by heart or learning which steps to take in a particular sequence.”

Ewout: “In everything we produce, there’s a lot of focus on making things as intuitive as possible, to optimise the use of the instrument and to minimise the manual labour requirements.”

Topcon entered the unmanned airborne systems market through a partnership with Ascending Technologies, which has been fully owned by Intel since January 2016. What are your expectations of the UAS market worldwide and where do you see the synergy with your other positioning solutions?

Ewout: “First of all, UASs and mobile mapping solutions in general – whether they fly, drive, however they move – are an exciting new data capture addition to our entire portfolio. The interesting thing about the drone or mobile mapping system is that it offers data capture possibilities for applications that are not traditionally in the survey field, so for all sorts of inspection purposes. The market for mobile visualisation or data capture solutions has expanded enormously, although it is still early days for the market itself. Legislation is an issue in every country and, although we’re slowly moving towards national and then international standards, that process will take a while. That’s also why there are so many drone manufacturers; it’s still a very local business because you need to understand the local needs and requirements. Big companies such as DJI and Intel have stepped in over recent years, and that is the next phase. We have chosen not to invest in developing drones ourselves. Instead, we are partnering with what we believe to be the leading drone manufacturers, Ascending Technologies and MAVinci – both of whom have been acquired by Intel, by the way, which means that Intel is currently a valued and appreciated partner of Topcon.”

And how does Bentley view the UAS market?

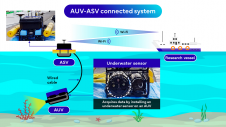

Ted: “I too prefer the term mobile mapping because that’s broader than drones only. It covers the mobility of an aircraft, but also the mobility of a vehicle-mounted scanner or the mobility of scanning and inspecting on the water. I see two ‘waves’ in that marketplace: the high-precision drones that Intel/Topcon is specialised in, which require geometric accuracy, a long time in the air, a lot of data storage, for professional and high-end geodetic use. There’s also the more consumer-type drones, which are very small and low-cost. These type of drones have their own advantages, such as they use swarm technology to monitor on another’s position in the sky. For inspection purposes you often only need images, without precise accuracy, which makes low-cost solutions very suitable. Hence the drones that are used for general inspection and image collection will remain a separate market from the very specific high-end drones for high-accuracy mapping and surveying. These will be pursued by specialists who need the best equipment and will command a very different price tag. At Bentley we love both, as we want the inspection data as well as the accuracy data.

Ewout: “Drones are the first and very logical step towards fully automated robotic data acquisition. It’s still early days, so we’re trying to choose our partnerships carefully, but it’s definitely receiving our full attention. Mobile mapping in general is a core focus for us as a data acquisition company…”

Ted: “And for us as a data processing company!”

The 3D mapping of buildings is increasingly moving from mapping facades, roofs and other building exteriors and the surroundings to the indoor environment. How are you anticipating the needs linked to this trend?

Ted: “The surveying of indoor space is indeed a growing market opportunity and we encourage the capture of indoor geometry and textures just as much as outdoor. The circumstances are somewhat different, though; indoor surveying has its challenges because of lack of natural light and the confinement of space, which means that each room or space has to be captured separately and the data then needs to be put in the context of the entire building. But the technology already exists and is improving all the time. From a data processing perspective, today our ContextCapture is capable of creating texturised 3D (mesh) models of both photos and point clouds, so from a processing perspective we are ready to handle this growing market. We anticipate further growth in use cases of how the mesh model data will be ‘consumed’ or combined with other data sources, such as facilities management, sensor data, etc.”

Ewout: “The ability to map and survey our environment is highly technology driven. As technology in general advances — think of cloud, connectivity, super computing power in the palm of your hand and highly advanced 3D data capture, registration and visualisation tools — it is becoming possible to map our environment in all its visible dimensions in almost real time. GNSS has been a major driver leading to real-time positioning but, due to its limitation to outdoor use, the indoor mapping business still has a lot of development to go through. As new mass data technologies and new sensors are continuing to evolve, and get bundled into solutions via smart and powerful software, new possibilities like indoor mapping are opening up. Topcon and Bentley are at the forefront and are leading technology industry directions. So we’re actually not anticipating, but rather opening doors for many new applications.”

Manufacturing surveying equipment is highly procyclical from an economic point of view. How has Topcon managed to survive all the economic booms and busts for nearly a century?

Ewout: “The traditional survey equipment business is indeed generally procyclical. But as we have been driving market development through technology, we have been able to stay ahead in most downturns with exciting new solutions, offering improved ROI to help battle economic concerns. Especially in the construction market, our advanced positioning solutions are the basis for complete process automation, which allows our customers to significantly reduce costs and increase their efficiency and productivity.”

In 2015 Bentley acquired Acute3D providing Bentley with an application – ContextCapture – which automatically turns digital images into photorealistic 3D models. How does this acquisition fit within your portfolio?

Ted: “Since the acquisition, one of the major items that we have added is that we can also generate 3D models from point clouds as well as from digital images, and we are making this available as a web service too rather than only as an application. We have subsequently integrated the mesh model support into our MicroStation-based applications as well as in our information management solutions, and various ways of viewing and publishing the data via the web. So the solution and the data usage is now a fully integrated part of our portfolio, and a cornerstone addition of how we view the design, construction and management of infrastructure to be enhanced via continuous surveying, dependent on the users’ workflows.”

Both of you have a background as a professional surveyor. How do you envision the future of mapping and surveying?

Ewout: “Surveying is a technology-driven profession: for hundreds of years the technology enabled us to model and map our environment in pretty rudimentary 2D shapes and maps. As technological growth has become exponential, the opportunity for the survey profession has grown and developed exponentially as well. We can capture and model our environment in all its geometrical dimensions, in real time, and it’s allowing us to add attributes, planning and budgeting components. With technology re-inventing and obsoleting itself at such a rapid pace, the same concept applies to the survey profession and is opening up a whole new and previously unseen range of accurate modelling, management and planning opportunities. From that perspective, surveying is probably one of the most dynamic and exciting professions that one can think of!”

Ted: “Absolutely! I’d just like to add that the word ‘surveying’ goes well beyond just capturing geometry. New technologies allow surveying to happen continuously through new sensors and new data capture techniques like drones. The outcome allows a 3D texturised reality survey that can be combined with other data sources like IoT big data for comparison of what was constructed or what is designed with what is the reality as surveyed at any particular time. As a result, inspection can happen at any point in time and is now much easier to do repetitively. The rise in studying changes, construction progression or deterioration of infrastructure has increased the demand for rapid surveying. Hence I believe that the need for surveying, and the ongoing innovation of survey processes, is going to continue for many years to come.”

Ted Lamboo

Ted Lamboo currently serves as senior vice president of strategic partnerships at Bentley Systems, Inc. From mid-1994 to December 1997, Mr Lamboo served as senior vice president of sales at Bentley Europe, Middle East and Africa, and from January 1998 to January 2000 he served as president of Bentley Asia/Pacific, based in Australia. From January 2000 onwards, he served as senior vice president of international operations at Bentley Systems, Inc. Prior to Bentley, he served for 13 years at Intergraph Europe, the European headquarters of Intergraph Corporation. Mr Lamboo holds a geodetic engineering degree from the University of Utrecht in The Netherlands and several post-graduate diplomas in computer engineering and development. From 1979 to 1982, Mr Lamboo worked for Topographic Services, the governmental topographic mapping organisation of The Netherlands.

Ewout Korpershoek

Ewout Korpershoek is executive vice president of mergers and acquisitions at Topcon Positioning Group. He serves on the board of directors of Topcon Europe Positioning BV. He joined Topcon in 1991. Prior to his current position, he served as chief marketing officer (CMO) and senior vice president with global marketing and product management responsibilities for Topcon Positioning Group. Prior to his role as CMO, he held responsibility for all the European positioning business as managing director of Topcon Europe Positioning. He holds a MSc in geodesy from Delft Technical University. He has prior experience with the Dutch National Department of Roads and Waterways and has also worked in the software mapping business.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)