New Age of Vertical Construction Verification for Balfour Beatty

This article was originally published in Geomatics World.

It often takes several stakeholders to bring a construction project to life, and for vertical construction developments, there are added complexities with space restrictions and intricate designs to support the upward structure. It’s no surprise then that mistakes happen, but mistakes can quickly drain budgets and take years to rectify. Technology now exists that can spot mistakes before they’re even constructed, create intricate as-built models for verification against design, and do it all in almost real-time.

Avoiding mistakes is crucial in delivering a successful project, and efficiency and productivity are key elements for any contractor. With this in mind, Topcon Positioning Group approached leading construction group Balfour Beatty to assist in improving its verification processes with a more effective and efficient vertical construction workflow for a project in Surrey, England.

Cooper’s Hill, a multi-million-pound refurbishment of a Victorian Gothic building most recently used as student accommodation, started in early 2017. The transformation comprises of re-purposing the old building and construction of new steel-frame structures to create 78 luxury retirement apartments on the 66 acres of Magna Carta Park.

Finding a Solution

Balfour Beatty’s team found the usual process of scanning with costly specialist contractors coming to site, followed by waiting times for data to be shared and then analyzed, didn’t meet efficiency and productivity needs. They then looked into technology and software to improve the process when Topcon’s newest instrument, the GTL-1000 integrated total station and scanner, became the jigsaw piece that completed a fluid and effective workflow.

Guy Murphy, site engineer at Balfour Beatty, said “We’ve done traditional verification on projects for a long time at Balfour, but previously there haven’t been the tools available for us to make this a quick and simple process. With Topcon’s GTL-1000 feeding into its data processing tech, suddenly there’s a link between a decent, quick and effective scanning tool and an equally quick software environment for us to verify in near real-time.”

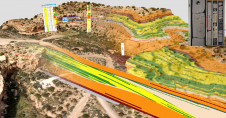

Murphy, who started on the project in July 2017, beta-tested the GTL-1000 as part of a full workflow including Topcon’s MAGNET Collage and ClearEdge3D Verity software that analyzes and verifies scanned data against design models.

“The GTL-1000 has enabled us to verify the project at any stage we wanted as it cuts the scan to verification process time dramatically. With the kit being dual-purpose, it fits into a site engineers’ daily work so it allows us to take on more capabilities without the need for thousands of pounds to be spent on scanning teams. It’s so simple to use and I haven’t needed any lengthy training courses to become proficient.” continued Murphy. “We’ve used this workflow on the new steel frame build to compare against the design models and we have been able to find mistakes and correct them before the materials were put in place. The Verity software shows us areas that are out of tolerance and enables us to consider designs and scans in much more detail than we’ve previously. We can’t exactly calculate the ROI because we just don’t have any mistakes made to compare timescales or budgets. The benefits we’ve seen from this new workflow and technology are unquantifiable.”

GTL-1000 Efficiency

Chris Emery, senior manager for vertical construction at Topcon Positioning Group, said “The industry to date has had its hand forced in the way it deals with mistakes – there’s been very little way to change the reactive nature to clashes and design issues. At Topcon, we knew the frustrations of engineers and contractors when it comes to verification – the time it takes, the money it costs and the specialist training required – and so our full workflow solution now makes it quicker and simpler than ever while saving money on reworks. We’re delighted to see the Balfour Beatty team are so pleased with the results of this new solution to date and it has been a pleasure working with them to fine tune this workflow so that we can enable the construction industry to fast-track vertical construction projects, saving time and money.”

The Cooper’s Hill project is the first to use the GTL-1000 with phase one due to finish on schedule in August 2019.

Nick Salmons, Balfour Beatty’s principal laser scanning surveyor, said “At Balfour Beatty, we are dedicated to driving innovative new working practices across our business as part of our ‘25% by 2025’ initiative. The new Topcon robotic scanning solution will increase productivity on site by accelerating the construction process and identifying design challenges more efficiently than traditional methods. We are delighted to have collaborated with Topcon over the last 12 months to trial this new tool, which will significantly benefit the industry as a whole; reducing cost and programme duration, for both clients and contractors alike.”

For more information, visit www.topconpositioning.com/gb/vertical-construction-solutions.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)