The Expanding Use of UAVs in Construction

Flying to Build a Better Product

It is an exciting time for geospatial professionals. The data that can now be obtained using unmanned aerial vehicles (UAVs, or drones) opens up previously impossible opportunities in many different industries. At the forefront of these is the construction industry. As a geospatial engineer working for a general contractor, Michael Schwind is always looking for new ways to utilize UAVs and the resulting data to improve efficiency and communication, and to detect and prevent costly – or even deadly – mistakes before they occur. In this article, he discusses some of the obvious and not-so-obvious ways that Fulton Construction, a general contractor based in Texas, USA, is employing UAVs to improve construction today.

There are many ways in which costly mistakes can be made in construction. The use of UAVs and the structure from motion (SfM) process enables the generation of spatial data that can be analysed within a geographical information system (GIS) or engineering software and overlaid with the various construction drawings and CAD files. This allows ‘as designed’ to be compared and contrasted with ‘as built’. The process of overlaying building design models over orthophotos allows professionals to catch spatial mistakes before they are set in concrete, literally. Digital elevation models (DEMs) provide a data product that is easy to understand and share, and that can be used to check the vertical characteristics of a job site. Furthermore, 3D point clouds make it possible to view and measure the job site in three dimensions.

A prime example of using an orthophoto and a CAD file to check the location of building elements can be seen when checking the location of embed plates – heavy steel plates that are set in the foundation of a building, providing a welding surface to attach the structural steel to the building foundation. If the embed plates are not set precisely, the structural steel will not be set in the correct location and will cause substantial problems later on in the project. Today, it is possible to create high-resolution orthophotos of the embed plate layout, overlay the embed plate CAD file, and not only check the location of the plates against the CAD file, but also measure the extent and direction of the offset (Figure 1). A map can then be created to illustrate the offset and this can be presented to the superintendent of the project for prompt correction.

Identifying Mistakes

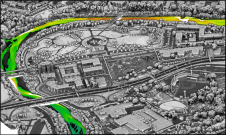

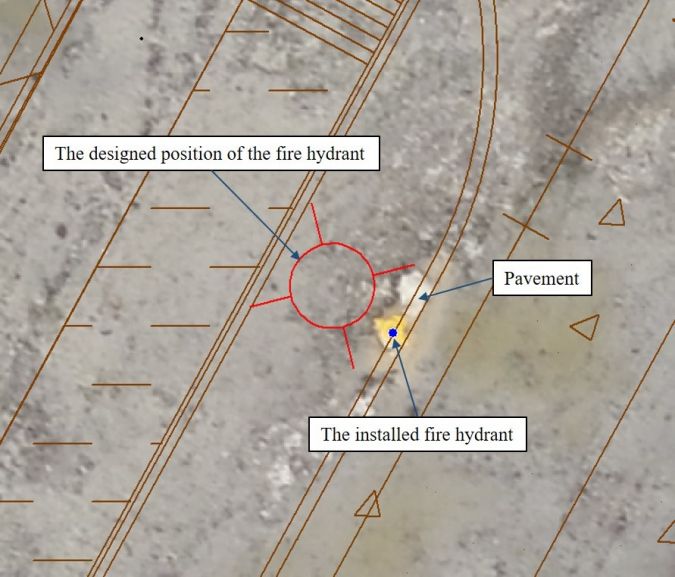

At Fulton Construction, we used the same method when checking the location of newly added fire hydrants at a school construction site. Seven hydrants were added to the site at the beginning of the two-year project. The superintendent of the project requested the creation of an orthophoto of the site in order to compare the location of the newly added fire hydrants to the future site pavement, which was to be added several months later. The orthophoto was created and overlaid with the project CAD file. It was discovered that one of the seven fire hydrants was installed approximately one metre east of where it was designed to be, causing a conflict between the hydrant and the site pavement (Figure 2). The contractor that had installed the hydrants was notified of the conflict and quickly relocated it to the intended position. Identifying this issue well before the pavement was constructed allowed us to get ahead of the issue before it became a larger and more time-consuming problem.

In another project, during the construction of a bank, there was concern that the pavement had low-lying pockets that would retain water after rainfall. To check this, a DEM of the pavement was created. The homogeneous nature of freshly poured concrete presented a challenge for the feature-matching algorithm of the SfM process. To overcome this, a low flying altitude was used to resolve the subtle features that the concrete offered. The low flying altitude also resulted in a highly densified point cloud that was necessary to detect any vertical discrepancies in the pavement. The generated 3D point cloud was cleaned, filtered and imported into a GIS to generate the DEM. The results gave us confidence in the pavement, as no low spots were detected and everything sloped in the direction as designed (Figure 3). A copy of the DEM was included in the monthly report to the project owner, providing extra confidence in the work that had been done.

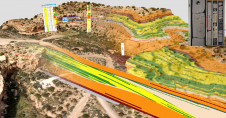

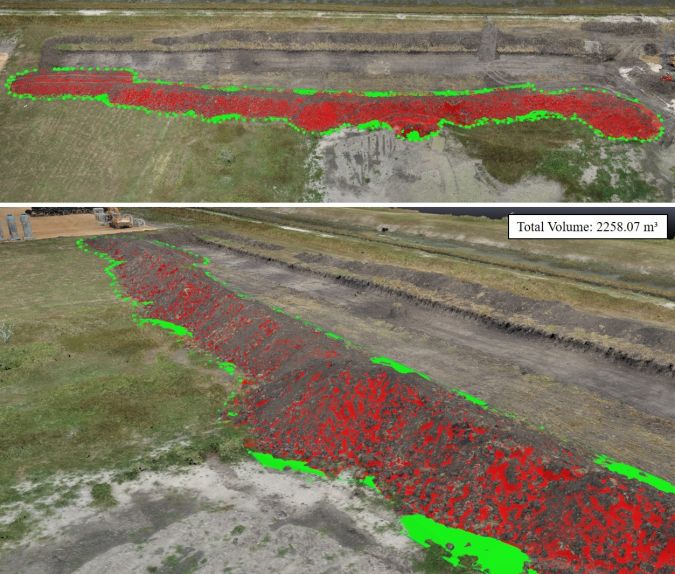

In a third project, after digging a large trench, we needed a cost estimate for hauling off the resulting stockpiles. These were quite extensive, covering an area of approximately 7,235 square metres. Surveying the stockpiles using traditional methods would have been time consuming and costly, and would not have provided the density of data points necessary to accurately estimate the volume of the soil. After only two hours, ground control targets were set and the UAV flown. The images were processed and the resulting point cloud was used to estimate the volume of material (Figure 4). An accurate estimate of the material protected us, the general contractor, from being overbilled and also protected the sub-contractor from underbilling themselves.

Communication through Data Sharing

We conduct flights two to three times a week on our larger job sites. Every flight is processed through our photogrammetric software to create orthophotos, DEMs and 3D point clouds. These data products are often imported into a GIS to create secondary data products such as contour lines, shapefiles and a variety of raster products. The vast amount of data that we collect on a weekly basis cannot be put to work unless it is shared in a format that allows the entire team to extract useable information from it. To accomplish this, we use a cloud-based data hosting service to store data that is pertinent to each job site. This cloud-based interface enables the entire team to view, analyse and create spatial data. It forms the missing link that connects the GIS and mapping experts to the project managers and superintendents.

Because construction projects are always changing, it is important to keep the owners, architects, project managers and sub-contractors informed of the project status. This can be challenging when the team is spread out across a city, state or even country. UAVs make it possible to quickly and effortlessly move around the site, capturing high-resolution photographic and video images of individual site elements or the entire site from a higher altitude. This project imagery can then be shared on a data hosting service and quickly disseminated to everyone involved. Frequent project updates provide the team with a greater understanding of the project’s current condition and help them to make informed decisions quickly.

Monthly reports are common practice and also important within the construction industry. Such reports, written for the owner of the project, typically contain information such as the amount of rain received throughout the month, a short narrative that describes major progress that was made, an updated schedule reflecting project goals, and photographs that show advances in the project. High-quality images taken with a UAV are nice additions to the monthly report, showing the project as a whole and adding a cohesive perspective of the site that is difficult to capture from the ground (Figure 5.)

Improving Safety

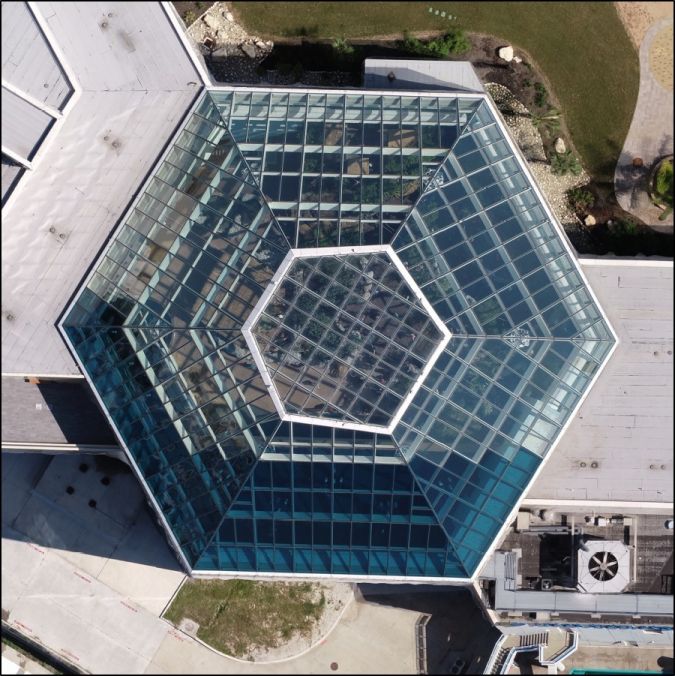

It is no secret that UAVs have improved safety for many construction workers. Any time a fall hazard is present, it is a simple and obvious solution to fly a camera to the area of interest rather than send a person. Most UAVs carry high-quality cameras that can capture high-resolution images capable of revealing small discrepancies in a structure. When a machine can do it, why send a person? For example, the Texas State Aquarium has a beautiful glass ceiling that crowns its newly added Caribbean Journey wing. Shortly after construction, we were requested to inspect a panel on this glass ceiling. The original plan of action was to send a person carrying a camera to the top of the building to inspect and take photographs of the glass. However, the incorporation of UAVs into our workflow made it possible for us to fly the camera above the ceiling and take high-resolution photographs without having to risk anyone’s safety (Figure 6). As an added bonus, we were also able to create a georeferenced orthophoto from which we could extract additional information.

Nearly three years after Hurricane Harvey decimated parts of the Texas coastline in the summer of 2017, efforts to repair the damage caused by the storm are still ongoing. We were asked to use our UAV to inspect the damage sustained by the steeple of a church in Corpus Christi so that the church could get an estimate for the repair costs. The UAV was flown on all four sides of the structure, taking photographs and video images of the damage. The church was then able to send the data to an engineering firm where it was used to determine the best plan of action and the cost of repair.

Conclusion

I am asked nearly every day to use a UAV to find answers to a question. Whether it is simply taking photographs so that a site assessment can be conducted, or determining the cut and fill volume before the construction of a car park, there is no shortage of ways in which a UAV can be put to work. It will be exciting to watch as UAVs become more prevalent among the workforce and to see the creative ways in which they continue to be utilized in the construction industry.

Value staying current with geomatics?

Stay on the map with our expertly curated newsletters.

We provide educational insights, industry updates, and inspiring stories to help you learn, grow, and reach your full potential in your field. Don't miss out - subscribe today and ensure you're always informed, educated, and inspired.

Choose your newsletter(s)